The power in our seafood industry

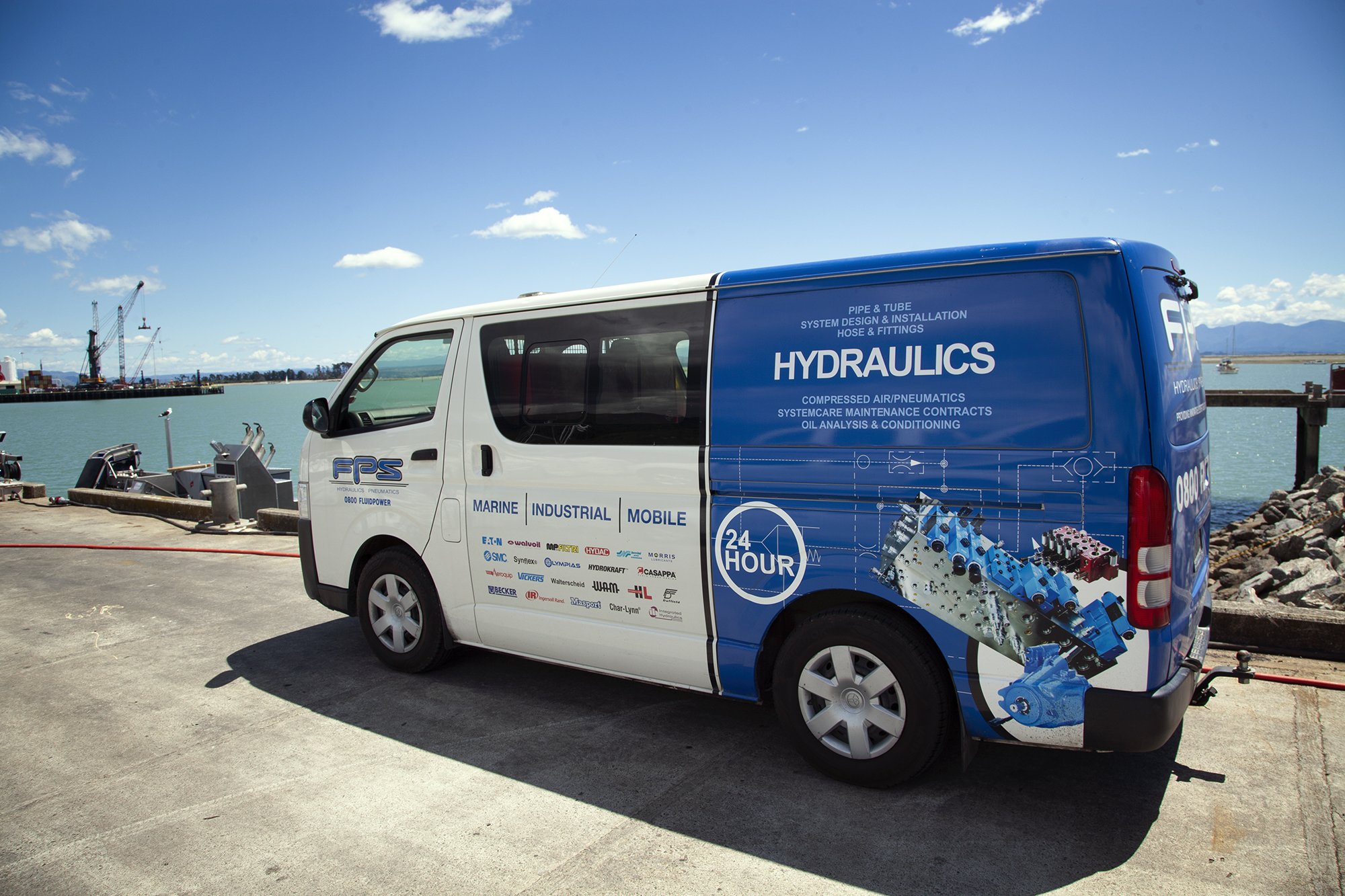

You might see their vans regularly across the Te Tauihu (the top of the South Island), but it is the innovation and engineering inside FPS’ Port Nelson workshop that is the driving force behind many of our industries across New Zealand, including the seafood industry.

It is this innovation and design capability that has set FPS apart as experts in hydraulic and pneumatic engineering.

For the past 20 years, they’ve been dedicated to working alongside their partners across many industries, coming up with innovative new ways of doing things that not only keep people safe but contribute to better ways of working.

Behind the helm

FPS was established as Fluid Power Solutions some 20 years ago. At the helm is industry stalwart, Gary Allen. Gary, who is FPS’ sole director and majority shareholder, says that because hydraulic technology is so fast-moving, the opportunities for innovation are always growing.

“Hydraulic systems have come a long way as our knowledge grows and new technology develops. I’ve been working in this field for over 45 years now and have seen a lot of exciting developments in that time.

We’ve worked on many maritime industry projects over the years, from hydraulic mooring systems in the UK, upgrades and new installs for on-shore and at-sea factories, fishing vessel winch systems, complete boat refits to new builds, and much more. One of the most exciting recent developments I’ve been part of is the new safety systems for Sanford’s aquaculture fleet.”

Alongside Gary is a team of 35, including skilled engineers and specialists. One of these being FPS’ other shareholder and Sales Engineer, Owen Little. Owen has worked around the world and is another powerful name in hydraulic engineering.

Innovation and excellence

Innovation and excellence is embedded in everything the team at FPS do. The work done in the fishing and aquaculture industries is no exception and is a culmination of decades of hydraulic engineering experience in these industries.

FPS’ marine industry expertise focuses on increasing component reliability, eradicating corrosion, reducing downtime, safeguarding people, reducing component noise, decreasing fuel consumption, and improving harvest and production rates through better hydraulic efficiency.

Sanford has adopted many of FPS’ innovations. From a 10-tonne purpose-built marine grade deck winch for ‘The Pacifica’. To an innovative new safety system across unlike anything available today for their vessels.

The completely marinised winch system, like all the FPS manufactured marine components overcomes the issues FPS have found with other winch systems over the years – offering a promise of longevity unlike anything else on the market.

Designed and manufactured by FPS – for unrivalled excellence

One of Gary’s first hydraulic jobs was on Talley’s first Amaltal vessel some 45 years ago and still today, Gary and the team at FPS are still working on Talley’s fishing vessels, albeit a much larger fleet.

FPS designed and manufactured remote control systems, crane winches and flow controls are just some of the of the customised marinised componentry on board Talley’s fishing fleet today. Talley’s were early adopters of the specialty marine grade technology from FPS, recognising the importance of gear and componentry that increased efficiency and component life.

FPS know that hydraulics are integral to the performance of many work boats, and that they must work effectively and efficiently to ensure productivity. Their purpose-built stainless-steel components have been developed to withstand the harsh marine environment and resist corrosion, while remaining easy to maintain and repair.

Another vessel you will see purpose-built marinised components on is the recently commissioned Vanguard, built by Q-West.

“The remote controllers, winches, extension cylinders, thrusters, water pump and other components have all been designed with purpose-built stainless-steel components that are marine-friendly. Unlike off-the-shelf products, water and salt won’t corrode these custom pieces, meaning they’ll have a long life,” says Gary.

“Our marinised remote controllers are being used on mussel harvesters, fishing trawlers, purseiners, and other vessels, and have been for over 10 years. We’ve not had a single failure yet. It’s exactly the kind of customised solution we do all the time for our customers.”

Helping keep the noise and cost down

Another innovation driven by Sanford, is a noise control solution that has seen a reduction of up to 50% noise pollution and vibrations on their mussel boats.

“To reduce the noise on the boats, we looked at the way the pumps were installed to understand how the noise was being transmitted, and then worked out ways to reduce it. A lot of noise is transmitted from the pipes or pumps into the hull through vibrations. So, we came up with solutions to isolate the whole system from the hull using our own range of purpose-designed isolators and noise suppressors. The isolators also allow us to simplify the pipe-work installations.” Says Owen Little.

Sanford engineering manager Darren Brown said the suppression systems have made their boats safer for crews while reducing noise pollution for neighbouring users within the marine environment.

“Noise and vibration leads to fatigue for our crews. It’s also critical that we’re good neighbours to our fellow water users, so the less noise the better. The FPS system has had an immediate and significant impact for us. We reckon it creates a 50% reduction in noise and shock,” says Darren.

Gary says their fuel conscious systems are another way they have supported the marine industry recently. “We know our marine clients are paying attention to the cost of fuel these days. It’s expensive to operate a work boat year-round. Our goal is to always lift our game on fuel efficiency.”

Innovation won’t stop

Innovation is never ending at FPS and the ways in which hydraulics contribute to making our industries more safe, sustainable, efficient and productive keeps evolving.

“We’ll never stop finding ways to do something better,” says Gary. “At FPS that’s just a given and why our customers remain loyal and keep coming back to us to find solutions decade after decade.”